— PRODUCTS —

Tel (86)18676762429

Tel (86)18676762429 Address: No. 173, Chunteng Road, Gaoxin District, Zheng zhou ,Henan, China

Email: maceyliu@shuangfusl.com

Tel: (86)18676762429

RUBBER EXPANSION JOINT

Product Description

Features

• Wide Flowing Arch Design

• High Pressure Rating than Normal Expansion Joint

• lntegrallyflangedesign,nogasketrequired

• Galvanized Steel Retaining Rings Standard

• Virtually Eliminatc Sediment Buildup

• Excellent Chemical andAbrasion Resistance

• Absord noise,Vibration and shock

• ANSI 125/1 5OLB Flange Drilling

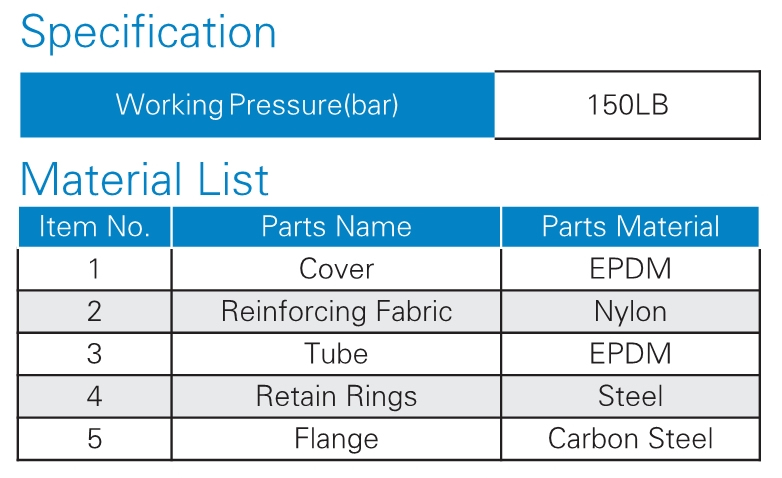

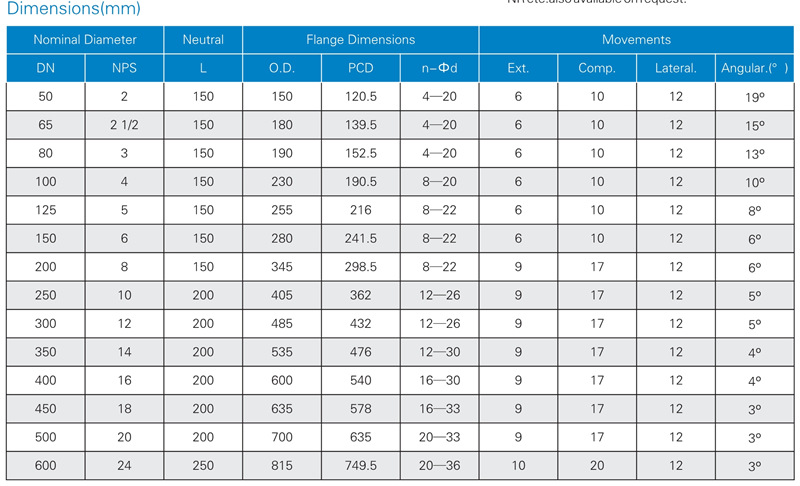

*Other rubber material such as nitrile,Hypalon, NR ete.also available on request.

Above flange acdto ANSI B 16.5,Other flange such as DINBS,JIS etc.also all a vailable on request.

• Note:

1 All expansion ioints are finished with retaining flangeslimit rod units are available on special request.

2.Pressures shows are recommendedoperating,test pressure is 1.5timesoperatingburst pressureis 3 timesoperatlng.

3.Vacuum rating is based on neutral installed length without external load.products shall not be installedelongatedon vacuum applications.

4.Do not weld near the expansion ioints or weld the steel flanges to the piping ufter the expansion joints are installed.This will either burn or seriously damage the expansion joints.

Control—Units

Generally,control units are always recommended as an additional safety factor,preventing damage to the joint and the associated equipment.

Features

• Protects Expansion Joints from Over—Expansion and Over—Compression.

• High Tensile Galvanized Steel Rods,Stainless Steel and Other Material is available on request.

• Galvanized Gusset Plates,Stainless Steel and other Material A vailable.

• Rubber Grommets Isolate Vibration are stabdard for all the size.

• Spherical Washers Available and Prevent Binging while Minimzing Lateral Forces.

• Double Nuts are used to Lock Limit Points and allow for Field Adjustment.

• Other Standard Drilling Available,including DIN,BS,EN,UNI,JIS,ANSI etc. Universal Tied/SeIf—Cuiding Control Units Available and Prevent Squirming on Longer Expansion Joints.

Suggestions for installation and maintenance

1 Clean all foreign matter and remove burrs or sharp edges from flanges.

2.All pipe lines should be properly supported,so that the expansion joints do not carry the pipe load.

3.Remove burrs or sharp edges from flanges.

4.Do not install joints on raised face flanges of more than 1/16.

5.All pipes are to be lined up accurately before installing expansion joints.

6.Bolts should be on the inside of the joint flange,Metal washer must be placed at the facing of the split retainingring.

7.Bolts shoud be tightened by alternating around the flange and all tightened equally.

8.Bolt tightness should be checked one week after going on stream and periodically thereafter.

9.lf system is not anchored to insure against movement beyond maximum stated limits,a control unit must be used.

Pro Links